-HDPE Pipe

─ Overview

HDPE Pipe

Overview

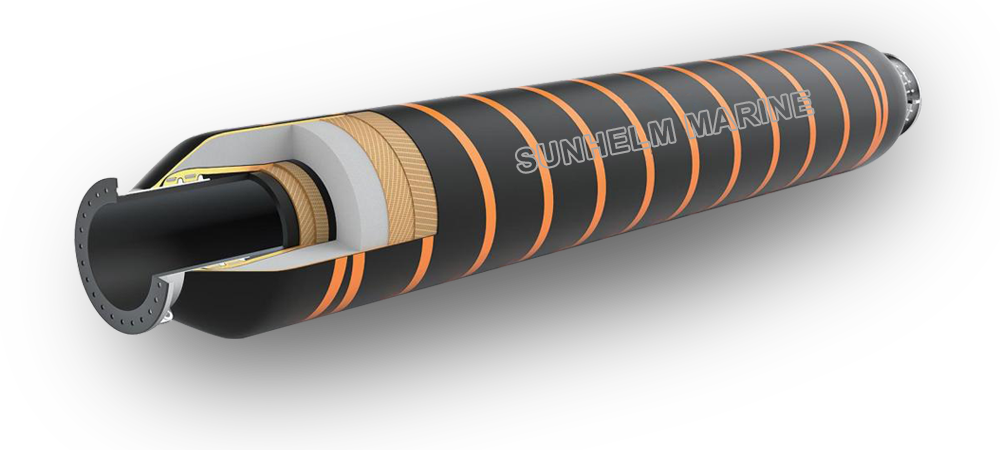

Piping made of polyethylene is a cost effective solution for a broad range of piping problems in municipal, industrialmarine, mining, landfill, duct and agricultural applications. t has been tested and proven effective for above groundsurface, buried, sliplined, floating, and sub-surface marine applications.High-density polyethylene pipe (HDPE) can carry potable water, wastewater, sluries, chemicals, hazardbous wastes.and compressed gases. Polyethylene is strong, extremely tough and very durable.

─ Feature & Applications

HDPE Pipe

Feature & Benefit

Feature & Benefit

- High corrosion resistance, resulting into a longer life.

- High impact strength.

- Extremely light weight and hence easy to handle.

- High flexibility.

- High abrasion resistance.

- Earthquake resistance.

- No infiltration, helps maintaining the quality of fluids being conveyed.

- No trenches needed, resulting into easy and economicalinstallation.

- High UV resistance to scaling and biological build upAllows fusion to eliminate leakages.

Applications

- Marine, mining, landfill, duct and agricultural applications.

- Carry potable water, wastewater, slurries.

- Chemicals, hazardBous wastesand compressed gases.

─ Factory

HDPE Pipe

Manufacturer

SunHelm Marine specializes in the production of engineering products for dredger dredging pipelines. Sunhelm Marine has more than 20 years of production experience and has built large-scale production workshops with an indoor storage area of 12,000㎡. SunHelm Marine is a leading manufacturer of dredging pipeline products.

SunHelm Marine has the ability to produce dredging mud suction and discharge hoses with a maximum diameter of 1100mm and various types of special steel pipe floats for dredging. SunHelm Marine relies on various advanced testing facilities to accurately control product quality.

─Structure

HDPE Pipe

Technical Parameters

Specification | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 |

Pressure | 0.6Mpa | 0.8Mpa | 1.0Mpa | 1.25Mpa | 1.6Mpa |

DN(mm) | thickness (mm) | thickness (mm) | thickness (mm) | thickness (mm) | thickness (mm) |

110 | 4.2 | 5.3 | 6.6 | 8.1 | 10.0 |

160 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 |

180 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 |

200 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 |

225 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 |

250 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 |

280 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 |

315 | 12.1 | 15.0 | 18.7 | 23.2 | 28.6 |

355 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 |

400 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 |

450 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 |

500 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 |

560 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 |

630 | 24.1 | 30.0 | 37.4 | 46.3 | 57.2 |

710 | 27.2 | 33.9 | 42.1 | 52.2 | 64.5 |

800 | 30.6 | 38.1 | 47.4 | 58.8 | 72.6 |

900 | 34.4 | 42.9 | 53.3 | 66.2 | 81.7 |

1000 | 38.2 | 44.7 | 59.3 | 72.5 | 90.2 |

1200 | 46.3 | 57.2 | 70.6 | 88.2 | / |

1400 | 53.9 | 66.8 | 82.4 | 102.9 | / |

NOTE: Upon availability. Tolerance on length: ± 1 % (ISO 1307 Standard). | |||||

─ Supporting

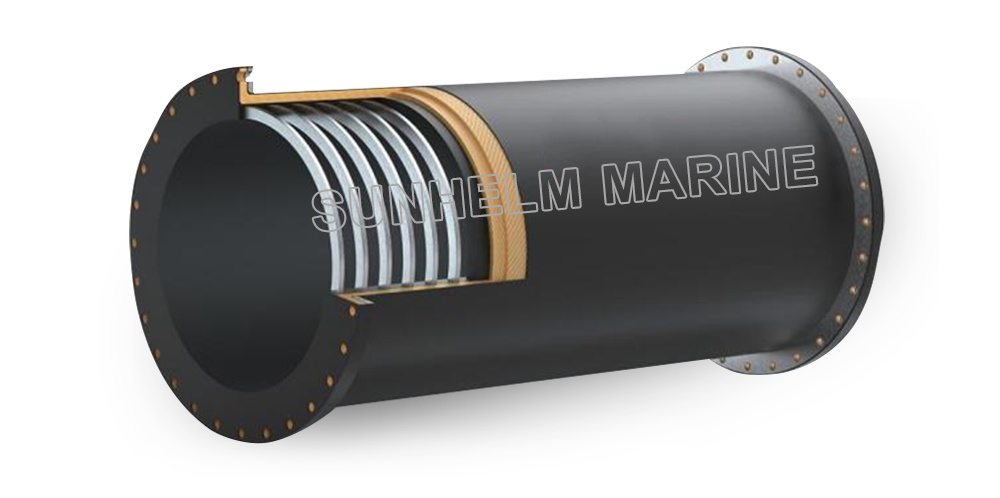

Pipe Floats

Overview

Pipe floats are the flotation of pipes, hoses, and cables for dredging, mining, and marine applications.

They are always used with HDPE pipes, steel pipes, and rubber hoses to make the pipelines can work on the water. Besides, The pipe floats are an easy-to-install solution, which allows pipes to bend, while maintaining low resistance to waves, wind, and current.