- Discharge Dredging Hose

─Overview

Discharge Hose Overview

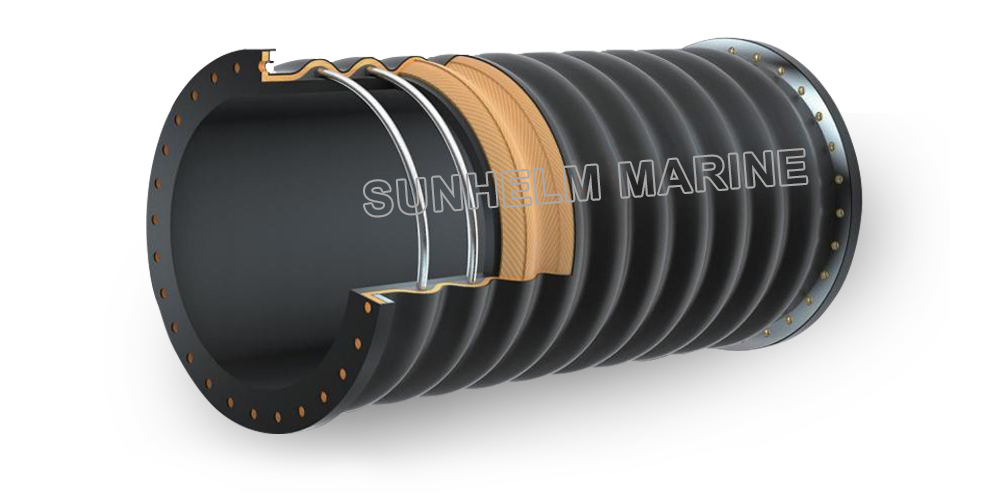

Discharge dredging hose is part of dredge pipeline for dredger, usually with the pipe floater, HDPE pipe, or steel pipe connected in one set of pipeline. In the working environment with high wind and waves, the discharge rubber hose can rely on its own softness to offset part of the wind, so as to ensure the safety of the whole pipeline.

─ Benefit

Discharge Dredging Hose

Feature & Applications

Feature & Benefit

- Abrasion-resistant and bending-resistant.

- Easy to install, flexible to use and safe.

- High impact resistance.

- Good wear resistance, flexibility and anti-scratch ability.

- The suitable working temperature: from -20℃ to +50℃.

Applications

- Used at port, dock for discharging sea water, silt, sand, flood, etc.

- Particularly suitable for work of dredging operation dock and port, Building project and soon.

─ Factory

Discharge Hose

Manufacturer

SunHelm Marine specializes in the production of engineering products for dredger dredging pipelines. Sunhelm Marine has more than 20 years of production experience and has built large-scale production workshops with an indoor storage area of 12,000㎡. SunHelm Marine is a leading manufacturer of dredging pipeline products.

SunHelm Marine has the ability to produce dredging mud suction and discharge hoses with a maximum diameter of 1100mm and various types of special steel pipe floats for dredging. SunHelm Marine relies on various advanced testing facilities to accurately control product quality.

─Structure

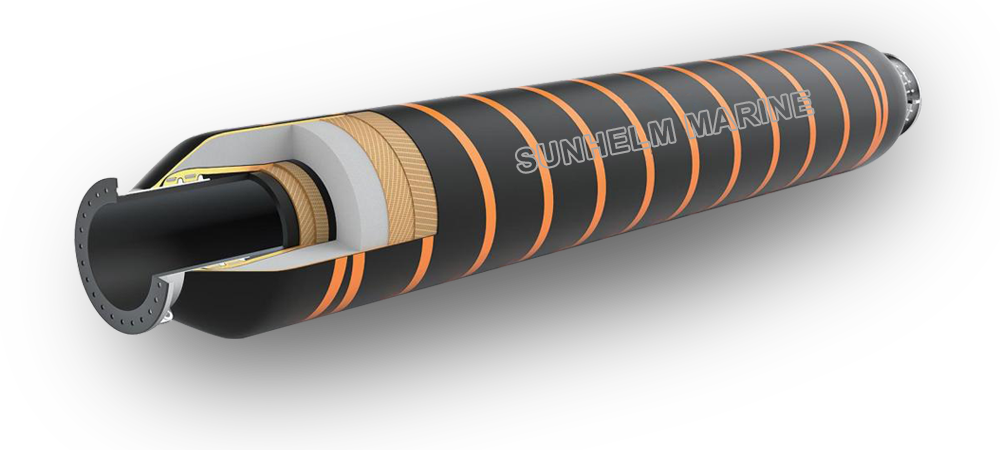

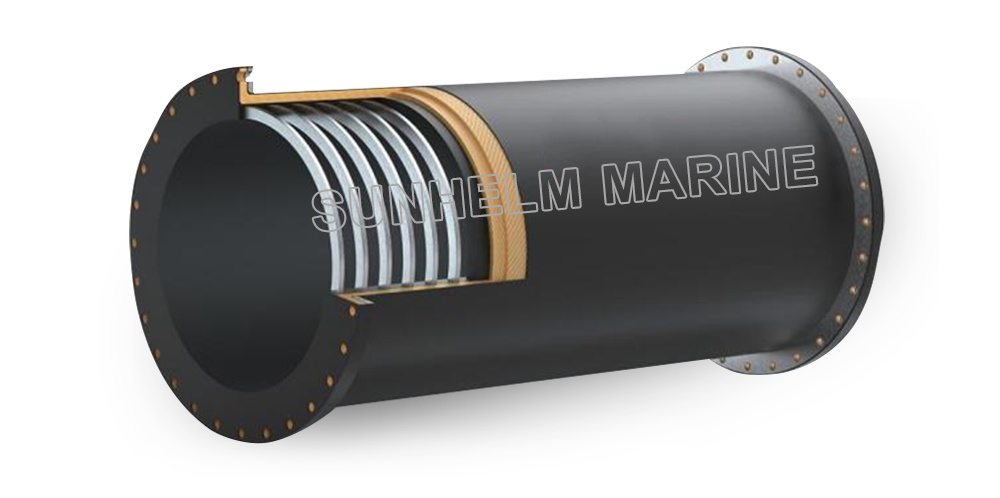

Discharge Dredging Hose

Technical Parameters

size(inch) | I.D.(mm) | W.P.(bar) | Length(m) |

8 | 200 | 10~35 | 1~11.8 |

10 | 250 | 10~35 | 1~11.8 |

12 | 300 | 10~35 | 1~11.8 |

16 | 400 | 10~35 | 1~11.8 |

20 | 500 | 10~35 | 1~11.8 |

24 | 600 | 10~35 | 1~11.8 |

26 | 650 | 10~35 | 1~11.8 |

30 | 750 | 10~35 | 1~11.8 |

32 | 800 | 10~35 | 1~11.8 |

34 | 850 | 10~35 | 1~11.8 |

Note: ID900mm & 1200mm, custom parameters are available. | |||

─ Supporting

Pipe Floats

Overview

Pipe floats are the flotation of pipes, hoses, and cables for dredging, mining, and marine applications.

They are always used with HDPE pipes, steel pipes, and rubber hoses to make the pipelines can work on the water. Besides, The pipe floats are an easy-to-install solution, which allows pipes to bend, while maintaining low resistance to waves, wind, and current.